What’s ULTRA?

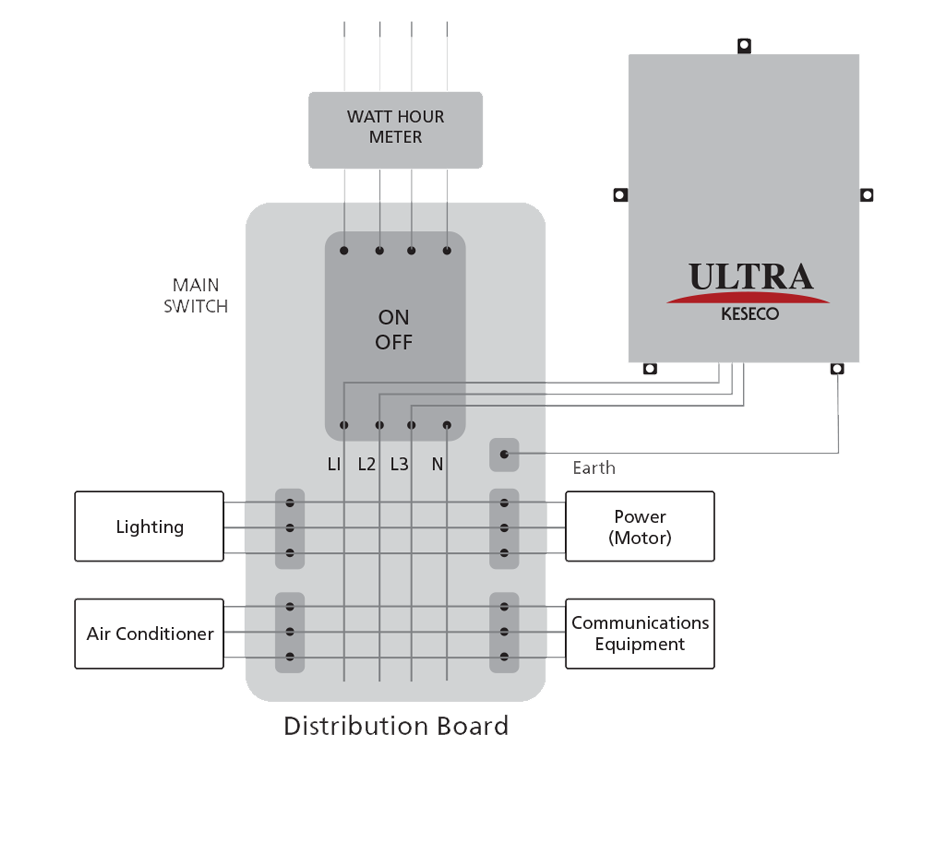

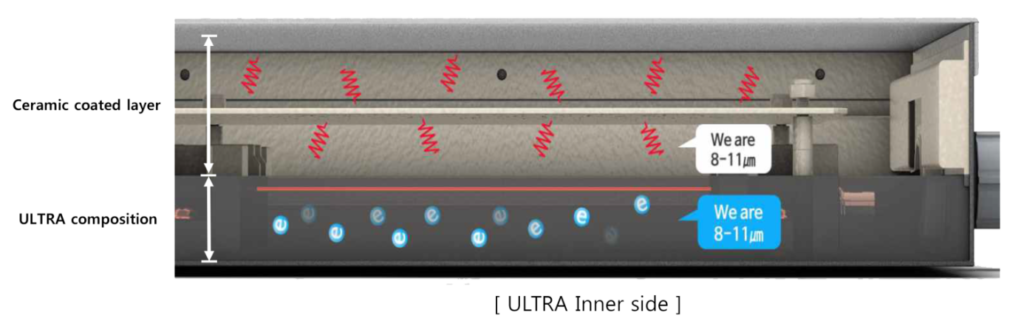

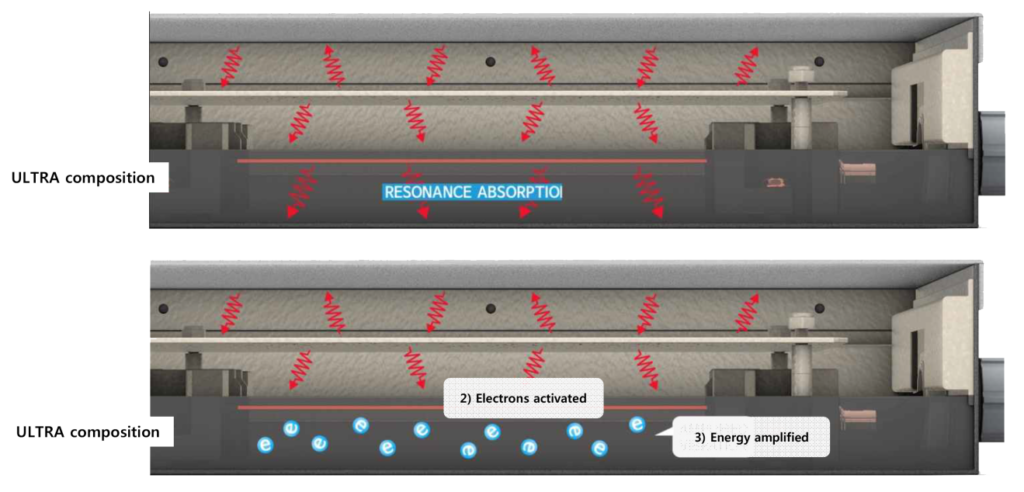

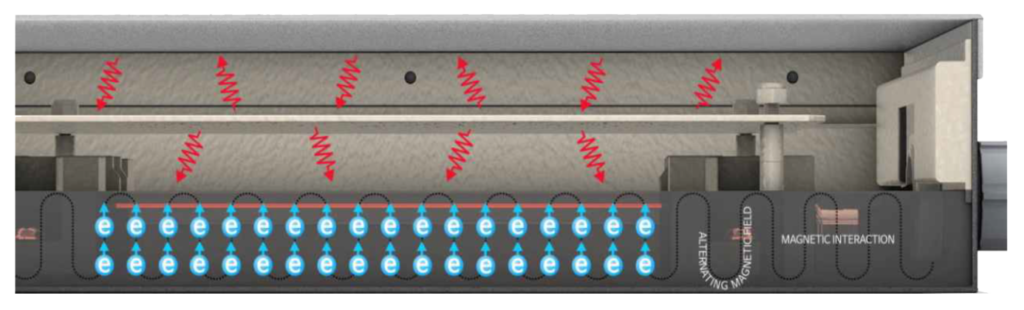

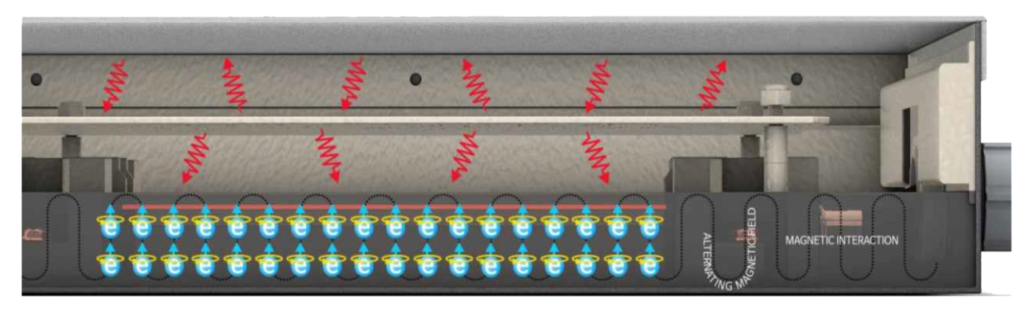

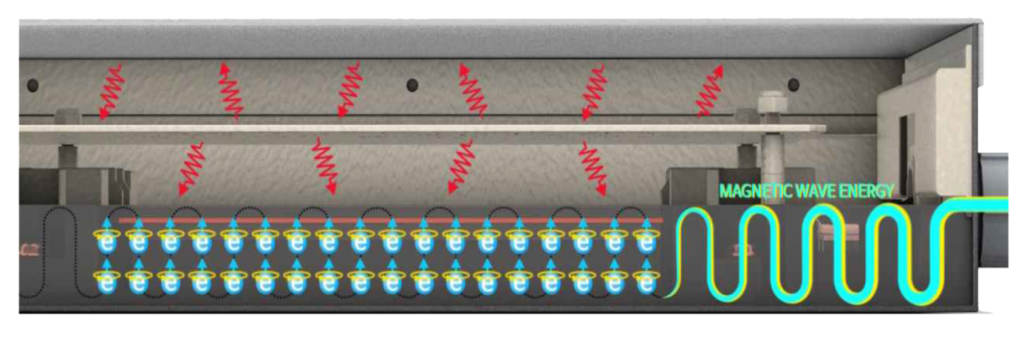

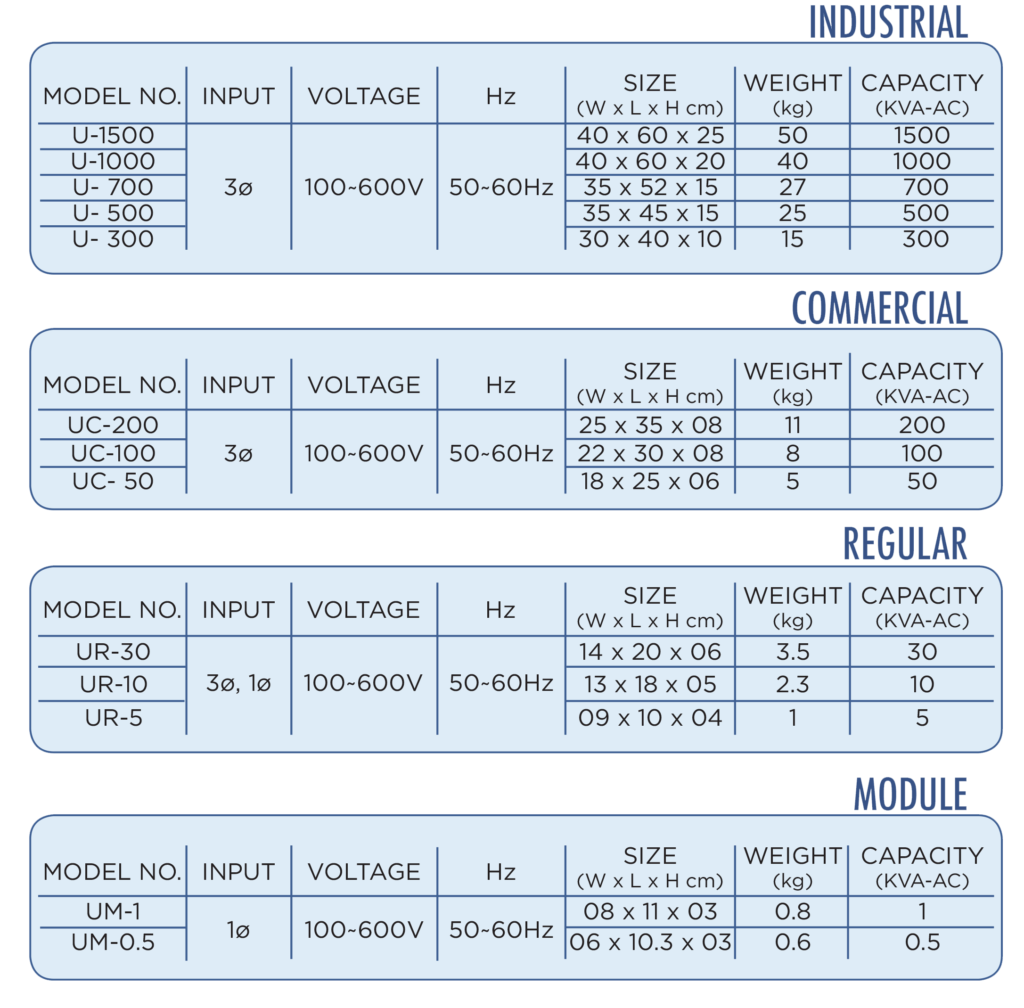

ULTRA provides a new approach to energy saving that combines state of the art technology with a range of models and bespoke installation to match our clients operational and energy consumption profiles. ULTRA will reduce an organizations carbon emissions and power consumption, delivering typical cost savings of 10-15% and a return on investment of less than 2 years.

Ultra can be installed alongside other existing energy saving solutions including Voltage Optimization, Power Factor Correction and Soft Start Technologies to deliver additional savings.